I've had my Casio VP-E Volume Pedal (which also works as an Expression pedal) for what is probably well over 30 years. So I wasn't hugely surprised when it started to get a bit noisy. Now it is very robustly constructed, with lots of aluminium extrusion, and it is a classic mechanical foot pedal, so it seems as if it would be a very good candidate for trying to fix - probably by replacing the potentiometer inside.

There are quite a few designs of foot pedal, ranging from simple passive mechanical designs (with levers or gears) through to sophisticated active electro-optical or magnetic circuits. The Casio VP-E wasn't crazily expensive when I bought it (to go with a Casio CT-1000, if memory serves me...), and you can see a white plastic lever when you move the top plate of the pedal, so it looked like it was a straightforward mechanical design.

Opening the VP-E is easy - there are three self-tapping screws that hold the metal end-cheek in place.

Self-tapping screws into aluminium extrusions was a standard way of making guitar pedals back in the 70s - I can remember a Carlsbro Flanger pedal built exactly that way from the late 1970s the was built that way. Not exactly an EHX Electric Mistress, but I'm sure it was cheaper... You can see one of the Carlsbro Flange pedals here... and (closer up) in this eBay advert (over $600!), although it will probably be gone by the time you read this... and here (from an effects database)... It's interesting to see that the Carlsbro pedal is now worth more than the CT-1000, although the Casio was a very early 'almost a synth' from Casio, but only two and a half years before the CZ-101 et al, which were definitely synthesisers!

So here's the mechanical arrangement. A bent (probably white (natural) nylon) lever, with a pivot underneath the foot plate on the top of the pedal, a second pivot close to the potentiometer, and result is that the potentiometer rotates a lot more than the foot plate. The 15 or so degrees of rotation of the foot plate is converted to something like 130 degrees of the 270 or so in a typical potentiometer. There are designs with gears that can do more, but this design is robust and has lasted decades for me so far.

It all looked very straight-forward, and so would be easy to fix myself. Remember that I've been doing this stuff for decades, so I have lots of experience. If you aren't sure, then go to an authorised, approved, qualified repairer or service centre and get a quote for what you want doing... Keep safe and carry on!

The short black piece of plastic (at the end of the white lever) is wrapped around the potentiometer shaft and tightened with a grub screw. Loosening this screw allows the lever to be moved out of the way.

Yep, as suspected, it is just an ordinary (for the 1970s or 80s) potentiometer - and easy to replace.

Now that it is exposed, the potentiometer nut can then be removed and the potentiometer unsoldered. Note how the wires are connected to it - take a photo with your mobile phone!

It is a 47 kOhm Logarithmic pot (short for 'potentiometer' - can't think why anyone would want to shorten that word!), indicated by the 47K and LogB labelling. European pots of this vintage are usually marked A for linear, and B for log, which is different to the rest of the world, where A often means log, B linear, and C anti-log.

Linear means that the output of the pot changes as you might expect when the shaft is rotated, so it outputs half when half way round. A logarithmic pot doesn't do this - some things just aren't linear. one example might be a frequency control - human beings hear octaves when a frequency is doubled, so if you had a linear pot, then going from 110m to 220 Hertz would be fine, but the next octave up is 440 Hertz (A3 or 4, and that's another story), and the next one is 880 Hertz, and the 1760 Hz. So if we used a linear pot to set frequency, then the low octaves would all be squashed up at one end, and the high octaves would be widely separated at the other end. A log pot would space the octaves out evenly as you rotated it.

Even though the intention is to get a control voltage from our expression pedal, the lever doesn't convert the rotation of the foot plate into rotation of the potentiometer shaft perfectly linearly, and so a log pot is used to give a 'compromise' that feels okay when you use it. Some high-end optical or magnetic expression or volume pedals have a much better relationship between the foot pedal movement and the output, but then they don't have pots inside...

If you feel like becoming a scientist, then you could try plotting the output of the pedal against the foot plate rotation. It ought to be linear-ish. Here's what I found with some of my 'basic' expression pedals:

I should point out here that I don't calibrate my expression pedals, and this is the first time that I've done any comparison process. I'm now wondering if I should do some work on getting them more closely aligned / linearised, although I don't use them interchangeably - they are each usually assigned to a specific role with a particular guitar pedal or synth. I haven't included my Yamaha FC-7 pedals because they are only ever used with my SY99 and Montage. If I was to try and align the pedals detailed here, then that would probably require some custom hardware and software, and that could easily turn into something expensive and time-consuming. I have worked on International Standards (I was one of the Editors of an ISO-MPEG standard...) and I'm not aware of a formal standard for expression pedals - but there are definitely two different ways of using the Tip and Ring connections. As always, my advice would be to use the expression pedal that is recommended by the manufacturer of what you are plugging the expression pedal into. So for my Yamaha synths, then that is the FC-7.

There are other types of resistance law as well, with various special audio tapers that are found in some amplifiers. If in doubt, then measuring the end-to-end resistance with a multimeter and then plotting the resistance from one end to the wiper, will quickly show if it is linear or logarithmic (or something else!).

There are several different types of potentiometer that are available: ranging from the expensive Cermet track material that has good thermal characteristics, through more modern 'plastic' materials, and finally to the cheap carbon tracks of ordinary 'basic' potentiometers. There are wire wound pots, but these are coarse and noisy, and would not be my first choice for a pedal.

eBay.co.uk rapidly provided a replacement pot, and this was quickly fitted. Well, I say quickly, but the soldering to the pot was very much 'old school' soldering, maybe from a person used to valve circuitry, because the wires were threaded through the holes in the three terminals tags, then wound around and soldered. This sort of arrangement doesn't fall off, even when all the solder is melted. Pulling at the wire, especially with molten solder present, isn't very good at removing the wire either - and it can spray molten solder everywhere. One effective technique is to cut the wire with cutters, close to the tag, and then to remove the remaining copper wire and use a solder sucker to clean it all up.

(One thing that the InterWeb has revealed to me is that the British pronunciation of 'solder' says the 'L', as in 'sole' 'duh', whereas the US pronunciation drops the 'L', as in 'sodder'.)

When replacing old pots, then don't forget that pots from the 70s will probably have 1/4 inch shafts (6.35mm), whereas modern pots are more probably going to be 6mm or even smaller in diameter...

Once the old pot was out, the replacement potentiometer shaft was cut to length, was soldered to the cable, was securely fastened in place with the star washer and the nut, and the lever and grub screw were tightened again to grab the pot shaft. Finally the end-cheeks were put back and the pedal tested with the multimeter again. The pot measured 50k as expected (tip to sleeve), and the wiper (ring) to ground (sleeve) varied from 28.9k to 2.2k. Not perfect for a volume pedal, but fine for CV/Expression use... and I could always adjust the angle of the pot shaft if I needed to...

I did contemplate buying a dual-gang pot so that I could have two separate outputs, but decided, based on the astonishing price of the decade-older Carlsbro Flanger pedal, that it would be better to leave it unmodified.

I now have a slightly smoother and less noisy Volume/Expression pedal!

Theory - Expression Pedals

Expression pedals, and in fact, any foot pedal that provides a Control Voltage that is used to control Expression or Volume in an electronic musical instrument, all tend to have similar designs, particularly at the budget end of the market. Although note that there are at least two different (and incompatible) ways to wire up the stereo jack plug (OK, the balanced jack plug commonly known as a 'stereo' jack), and specifically note that higher-end pedals might well have very different circuits and pin-outs because they use electro-optical or magnetic foot-plate rotation sensing methods.

Of course, you should always use the Expression pedal recommended by the manufacturer of the guitar pedal or instrument that you will be connecting the expression pedal to... but if there isn't a specific recommendation...

The circuit is very simple. The potentiometer (the fancy word for the electric component that a Roary control or Knob adjusts) has a voltage at one end, and ground at the other. The 'Wiper' then outputs a voltage between the voltage and ground, depending upon how mucho it has been rotated. At one extreme of rotation it will be the voltage, whilst at the other it will be ground. Most volume/expression pedals do not rotate the potentiometer through its full 270-ish degrees of rotation, and so the output never actually reaches the full range from voltage to ground.

As a side note, this is why many guitar pedals get you to use your Expression pedal when you set up the knobs that are going to be controlled by the expression pedal. By getting you to set the expression pedal to the two extremes (Toe and Heel positions) and then set the knobs where you want them for each extreme, then the guitar pedal knows exactly what the range of control voltages from the expression pedal are...

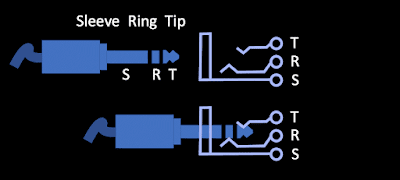

Some pedals have a switch that swap the ring and tip connections, so that the two main variations are covered. Most of my equipment seems to have the ring as the CV/Wiper connection, the sleeve as the Ground connection, and the Tip as the positive Voltage connection (which can vary from 3.3V (or lower) to 5V, depending on what it is powered from... As always, if you rewire anything, then you do so at your own risk.

Anyway, the 'swap' circuit uses a DPDT switch (Double Pole, Double Throw) and the circuit looks complex when the two positions are shown (above). The DPDT switch has two 'Either/Or' switches: so One input and Two Output (of which only one can be connected to the Input at any time). But if you think about how you would actually solder the wires to the DPDT switch itself, then the wiring is lots simpler - the input is on one side, the output is in the middle, with a pair of wires crossing over to give the 'swap' function. And that's it. Drawing the circuit out in full kind of makes it look more complex than the actuality.

I didn't add a switch to the Casio VP-E pedal, and I didn't add in the missing series resistor between the potentiometer and the CV point. I decided to keep the pedal 'as supplied'. If I was being technical, then my defence would be that the cable and the plug/socket have some inherent resistance, and so I would just be adding a bit extra.

Modding / Customisation Warning

Of course, you should always use the Expression pedal recommended by the manufacturer of the guitar pedal or instrument that you will be connecting the expression pedal to... Also, if you modify / change / rewire anything, then you do so at your own risk. If you are not confident of your ability (or your equipment is still covered by a warranty or guarantee) then you should go to an approved, qualified repairer or service centre for any repairs, modifications or customisations. Safe, not sorry, is the correct attitude to have.

*** 8th November 2021 ***

I have added a few minor corrections here and there, and will add a 'voltage output' chart as well in the next couple of days...

---

If you find my writing helpful, informative or entertaining, then please consider visiting this link:

Synthesizerwriter's Store (New 'Modular thinking' designs now available!)

No comments:

Post a Comment